Introduction: The Open Kitchen of Tailoring

In the culinary world, the most revered and confident restaurants proudly feature open kitchens, a bold declaration that they have nothing to hide—only craftsmanship, hygiene, and artistry to showcase. At Light Source Couture, we passionately apply this same philosophy of radical transparency to the art and science of garment manufacturing. We don't just welcome our clients behind the curtain; we actively invite them to walk the floor, touch the processes, and understand the symphony of precision that brings their designs to life. Our sprawling, state-of-the-art production facility in Shandong is far more than a mere assembly hall where fabric is joined. It is a dynamic laboratory of precision, a place where the relentless consistency of top-tier automation performs a delicate dance with irreplaceable artisanal dexterity and human oversight. From the silent, digital pulse of our computerized cutting room to the hiss and transformative heat of our steam-filled finishing stations, every minute operation is meticulously calibrated, monitored, and executed against one uncompromising standard: Perfection. This is a tour of the machinery, the metrics, and the human touch that defines our output.

Step 1: The Cut – Precision to the Millimeter

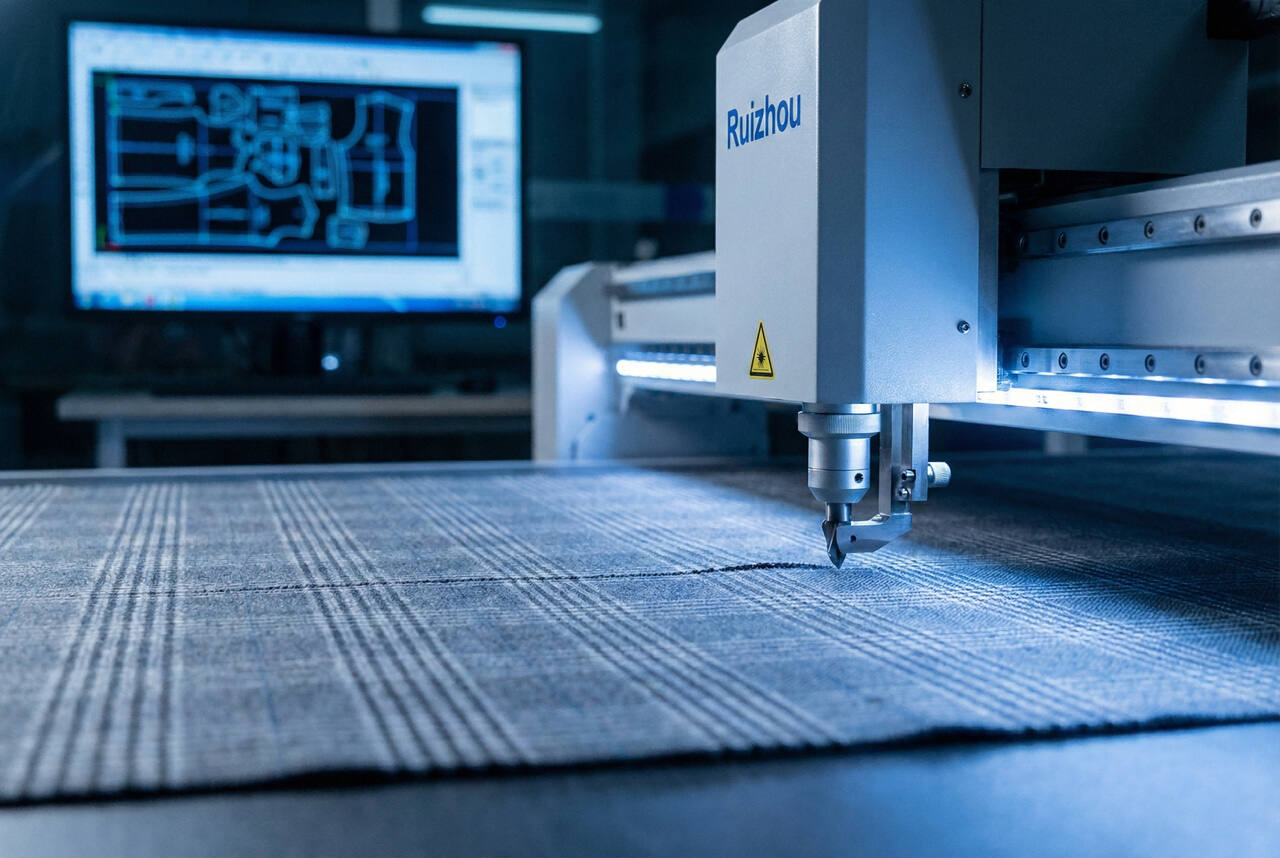

The journey of a great suit is irrevocably determined by its first cut. In conventional mass production, where cost and speed are paramount, fabrics are stacked dozens of layers high and cut in bulk with oscillating blades. This method, while fast, inevitably leads to friction-induced "fabric shift" between layers, resulting in pattern pieces that are subtly misaligned and inconsistent—a compromise unacceptable for the precision required in premium tailoring. At Light Source, particularly for our Made-to-Measure (MTM) and high-pattern-focus lines, we have invested in the Ruizhou Dual-Head Single-Ply Digital Cutter, a technological marvel that redefines accuracy.

The single-ply methodology is a game-changer for quality. By cutting just one layer of fabric at a time, guided by a high-precision vacuum table and a laser-guided cutting head, we eliminate layer shift entirely. This is non-negotiable for pattern matching, a critical hallmark of luxury. Whether your design features bold Prince of Wales checks, delicate pinstripes, or complex plaids, the Ruizhou system ensures absolute continuity. The stripes on a sleeve will align seamlessly with those on the body; the pattern on a chest pocket will be a perfect mirror of the jacket front. This meticulous attention to detail, often reserved for bespoke ateliers, is engineered into our commercial workflow.

Efficiency Without Compromise:

The "Dual-Head" aspect of our Ruizhou system is key to bridging the gap between bespoke accuracy and commercial viability. While one head is precision-cutting a complex jacket front, the second can simultaneously cut a trouser panel or a lining piece. This parallel processing allows us to maintain the throughput necessary for significant order volumes without sacrificing the millimeter-perfect accuracy that defines the starting point of a superior garment.

Hot News

Hot News